| You can see many solar cell modules in our today's life. They are equipped in calculator or on house roofs and so on. It is spread of solar cells to our society. Solar cells do not emit any waste materials and do not use any energy resource during power generation. In addition, since they are relatively small power generation devices, distributed power supply systems can be fabricated. However, there is a problem in solar cells as a industrial product, which is high production cost. Although the production cost for Si solar cells is rapidly decreasing, resulting total power generation cost is still high compared with other power generation systems. The reason of existence of goverment grant for solar cell module adoption is for alleviation the production cost. |

|

|

|

|

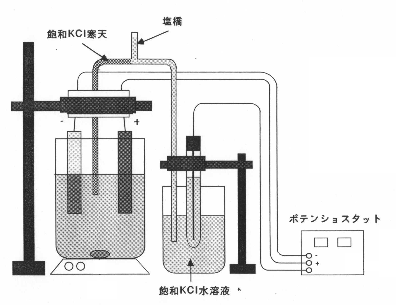

In order to reduce the production cost further, it is important to fabricate solar cells from easily obtainable materials by simple production processes. Our laboratory have studied an electrochemical deposition technique, which is a similar method to electroplating of metals, for fabrication of solar cell materials. This method is simply performed by conducting current between electrodes dipped in electrolytes containing basic chemical materials and resulting solar cell materials are deposited on surfaces of cathode electrodes. We have deposited many materials such as zinc sulfide (ZnS), tin sulfide (SnS) and zinc oxide (ZnO) by the electrochemical deposition. In particular, we have obtained the good deposition condition for fabricating good quality SnS films as solar cell materials. |

|

|

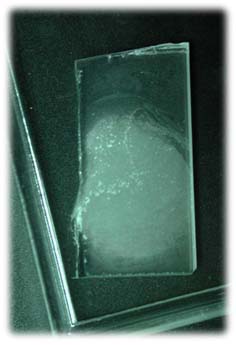

| Not only the electrochemical deposition, we have also developed our original deposition technique called photochemical deposition (PCD) for fabrication of solar cell materials. This method was discovered by a student in our laboratory from a trivial experiment and it is in public as a patent. The way of this method is that by irradiating intense light containing UV to aqueous solutions containing basic chemical materials the solar cell materials are deposited on the irradiated region. Although we have deposited cadmium sulfide (CdS) and cadmium selenide (CdSe) by this method, at present, we are tring to deposite ZnS and copper indium disulfide (CuInS2) because of consideration to the earth environment. |

|

|

|

|

Because Si solar cell technology has already advanced very much, we don't think that our new technique surely compete with it even in future. However, the important point of researches for such simple techniques is that the simple technique can be researched and developed in developing countries which cannot produce Si crystals. Countries requiring solar cell technologies are not only Japan and advanced country but also developing countries. Countries with difficulty to lay power cables really want to develop distributed power sources. We hope that, in future, mature of simple solar cell fabrication research helps economical independence of developing countries from advanced countries and reduces economic disparity in the world. |

|

|